Five benefits of waterjet cutting

Whether you are new to waterjet cutting or already manufacture with waterjet technology, it is always important to be aware of the benefits of waterjet cutting. This blog post explains five benefits of waterjet cutting, helping you to make a good quality business decision.

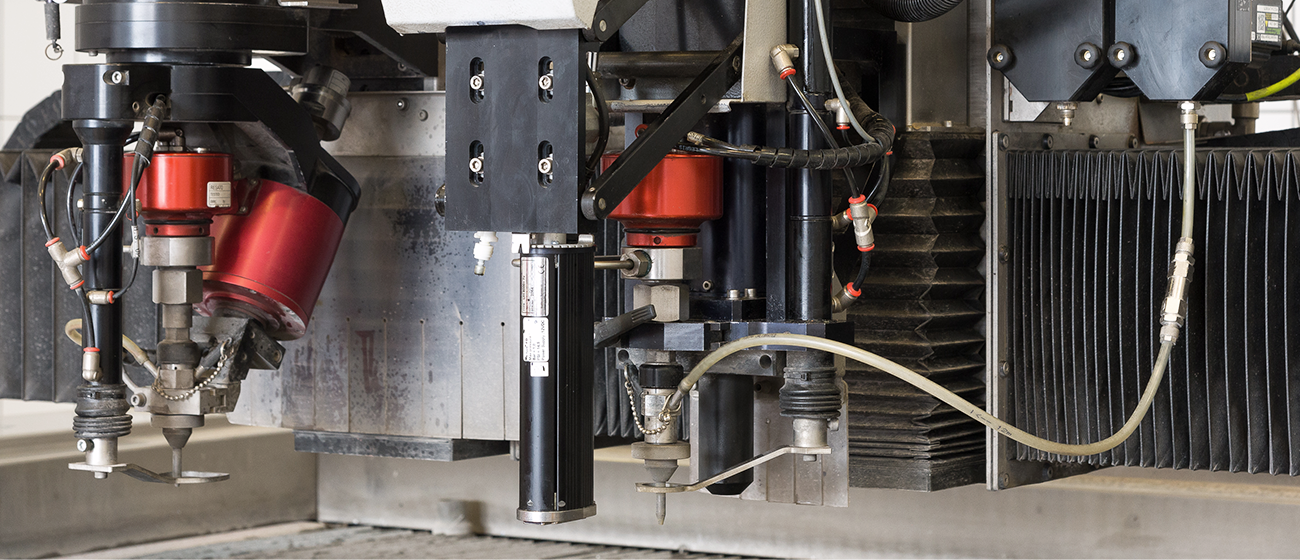

First of all, two kinds of waterjet cutting methods exist, namely pure and abrasive waterjet cutting. The difference is that pure waterjet cutting is used for cutting soft materials like foam or paper by using solely the water stream for cutting. Whereas, for abrasive waterjet cutting a granular abrasive is added to the water stream. The granular abrasive accelerates the power of the cutting stream, enabling hard materials such as metal or ceramics to be easily cut.

Below are five waterjet cutting benefits outlined, enhancing your overall waterjet technology know-how!

1. No material limitations

Waterjet cutting has versatile applications, cutting nearly any material; composites, plastics, metals, glass, stone or rock, ceramics, and rubber. With the addition of a granular abrasive, a waterjet cutting machine can perform quality cuts on materials up to 200 mm thickness.

2. No Heat Affected Zone (HAZ)

A major advantage of waterjet cutting is that no heat affected zone (HAZ) occurs due to its cold cutting method. Not only does cold cutting enable clean cuts, but also increases the operators’ safety significantly by eliminating the risks of burns.

3. No material distortion

Through its cold cutting method, the heat exposure can be bypassed, which is especially critical for materials like metal, leading to a fine cut without distortion in the material. This results in a smooth and burr-free cut.

4. No additional finishing process

The immediate high cutting quality ensures a precise result, avoiding an additional finishing process. This significantly accelerates the cutting process and saves time, increasing the overall efficiency.

5. NO HAZARDOUS WASTE

The growing importance of environmentally friendly processes throughout the industries is becoming more apparent. A significant advantage of waterjet cutting is that it does not create any hazardous waste in the form of fumes and gases, unlike other cutting technologies.