Description

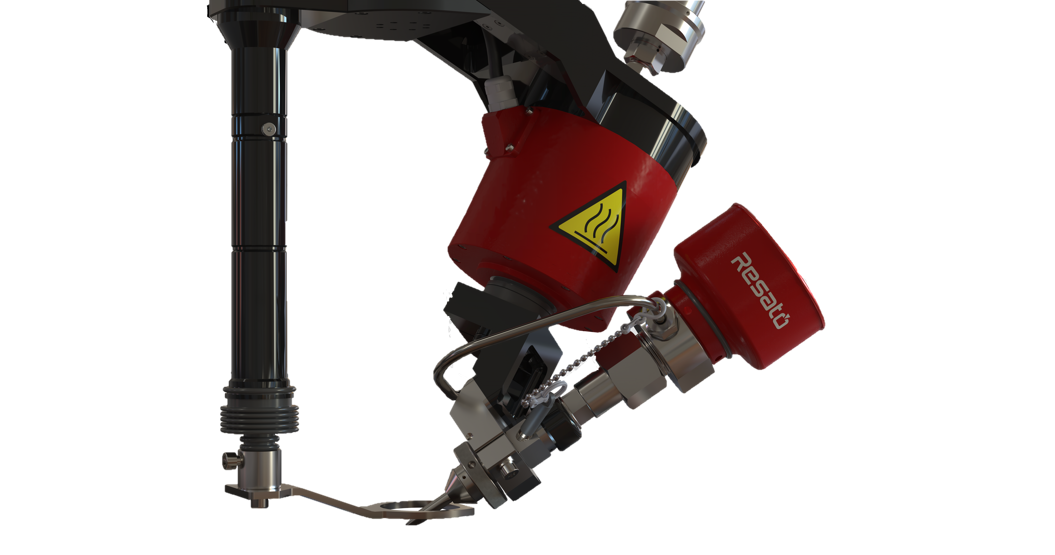

The 2.5D cutting head is designed to cut bevel parts from sheet material. Two additional servo-controlled axes are added to the standard XYZ axis creating a five-axis machine. In order to achieve a practical application a height sensor is integrated.

The integrated high torque frameless servo motors with hollow shafts are the core of this unique construction. Using the direct drive principle means a minimum of moving parts resulting in a compact, highly accurate, fast responding and maintenance-free solution.

The cutting head can be tilted up to 55º, the practical limit when cutting a 45º bevel corner in a 90º contour angle.

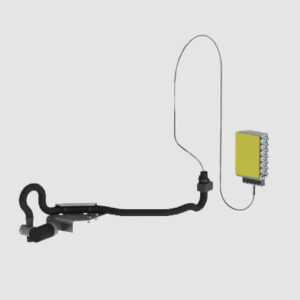

EMS System

Intended particularly for unmanned ACM operation, the electronic feeder is provided with the EMS electronic management system. Used with the cutting head it allows all key cutting parameters to be controlled. The EMS management system promptly detects a defective water nozzle or any stoppage in the abrasive feed, raises an alarm and can automatically stop the cutting process if required.

Technical specification

| 2,5D Cutting head | |

| Maximum tilt angle | 55° |

| Maximum rotation | ± 360° |

| Operating temperature range | 10-30 °C |

| Protection class | IP65 |

| Axis positioning accuracy | ± 0,1° |

The 2.5D Cutting head can be extended with several options and features to further improve your waterjet cutting performance.