Principles of waterjet cutting

It is the velocity that does the cutting, not the pressure….

We talk about setting the pressure for the waterjet machine so that we can make a cut but ultimately it is the velocity of the water with or with out an abrasive that really does the cutting. The formula for kinetic energy : KE = ½ mv2 where m = mass in kg and V = velocity in m/s, is the basic formula that determines how we cut materials with a waterjet.

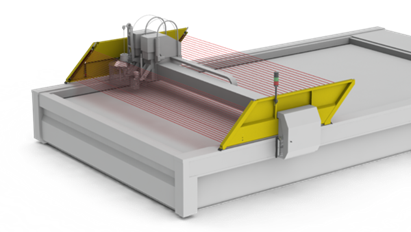

The principle of waterjet cutting is that we create a thin high speed water jet that concentrates it energy on a small area of the object we want to cut. By creating a (very) high pressure water flow and guiding that through a very fine orifice of typically 0.2 to 0.4 mm diameter we accelerate that water jet to speeds of around 700 m/sec, in excess of twice the speed of sound. The waterjet is led through the mixing chamber where it creates a vacuum with its high speed (venturi effect) and that is when we feed in a controlled amount of abrasive material. Typically it is a fine garnet , which is a mining product of a naturally sharp, hard stone. Alternatives to mined garnet are manufactured abrasives that are even harder such as aluminium oxide. It is with a waterjet and abrasive material that we do the cutting. The water is the hammer and the abrasive is the chisel and with that we can cut any material. Even a diamond!

In most applications 4000 bar is enough to create the required high speed jet. Higher pressure are available but at a great cost in maintenance and wear parts so that economically this is a limit that rarely makes economic sense. The high speed of the jet also limits the possibility to mix the abrasive with the water comprehensively. The water accelerates the abrasive using some of its own energy and a mixture of water with abrasive is led through the focus tube at a speed of about 600m/s. The fine waterjet hits the material with precision and will ‘drill ‘its way through for the penetration phase. During penetration the waterjet will make a small circle of a few mm diameter so that the jet does not lose its energy in splashback. After penetrating the material it ca continue to follow the cut line as programmed. Normally the operator will program a penetration just off the cutline so the jet can make a clean run into the cut line.

At pressures of 4000 bar in the high pressure pump, the pressure acting on the material surface can exceed 400 N/mm², necessitating the use of specialized materials and regular maintenance to ensure longevity and reliability.

Optimizing the parameters of a waterjet cutting system is a delicate balance between pressure, velocity, and abrasive flow rate. While higher pressures can lead to increased jet speeds and cutting power, they also pose challenges such as limited time for abrasive mixing and higher maintenance costs. Operating at the optimum pressure range ensures efficient cutting performance while minimizing wear on system components. Sometimes it is better to cut more slowly , leaving the machine to do its program in unmanned production.

In conclusion, waterjet cutting is a testament to the power of kinetic energy, to achieve precise and efficient cutting capabilities for any material. By understanding the physics behind waterjet cutting and optimizing system parameters, operators can use it to cut a wide range of materials from metals to stone, composites and ceramics to plastics and rubber. It will give a clean, burr-free and accurate cut ready for use.