Precision Redefined: Waterjet Cutting’s Role in improving Stone and Ceramic Joinery for Kitchen and Bathroom Furniture

Top end customers seeking perfection in the joinery of stone kitchen elements are driving a shift towards precision cutting tools. Simultaneously, a growing trend in cost-effective ceramic-based furniture, featuring a thin stone-patterned topping, is driving the need for more precision in stone joinery. In both cases, waterjet cutting has emerged as the preferred tool, offering both better precision and creative freedom to enable intricate designs.

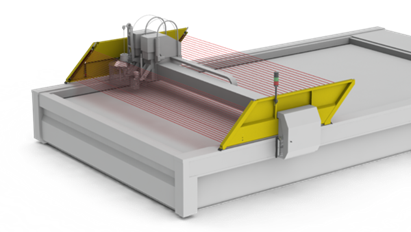

Waterjet cutting technology uses a high-pressure stream of water mixed with abrasive particles to achieve cuts with accuracy up to 01, to 0,15 mm precision. This stone cutting technology allows for intricate designs, curves, and patterns, ensuring that each piece fits seamlessly with its counterparts.

The volume and project market has witnessed an increased interest in cost-effective ceramic-based furniture, featuring a thin stone-patterned topping. The challenge lies in concealing the underlying ceramic plate effectively. Waterjet cutting addresses this challenge as the technology’s precision ensures that the thin stone-patterned topping aligns seamlessly with the edges of the furniture, leaving no room for the underlying ceramic plate to be exposed. This combination of ceramic plate and precision meets the demands of cost-conscious consumers but also elevates the overall quality of the furniture.

Waterjet cutting’s allows the use of a broad range of materials, from natural stone to ceramics, rubber or plastics. This makes it an ideal choice for manufacturers catering to diverse customer preferences in the kitchen and bathroom furniture industry. Whether crafting high-end, luxurious pieces or more affordable alternatives, waterjet cutting proves to be effective in achieving the required level of precision in joinery.

In conclusion, as the demand for precision in joinery of natural stone, composite, and ceramic-based furniture grows, waterjet cutting proves to be the most effective solution. It offers unparalleled precision in cutting and shaping, meeting the highest standards of quality and craftsmanship in the kitchen and bathroom furniture industry.