Description

The 2D cutting head has a long-life mixing chamber and only two wear parts: the water nozzle and the abrasive mixing tube. The cutting table’s bridge has 1 or 2 cutting heads, each mounted on a carriage plate. The carriage plates are provided with direct-drive linear motors, enabling fast and easy setting of the correct distance between both cutting heads from the operator console. This distance varies from 350 mm to 1500 mm. The ACM 3000-series machines also have a special feature: While using 2 cutting heads, the effective cutting range for 1 head remains 3000 mm in a 2D-cutting position.

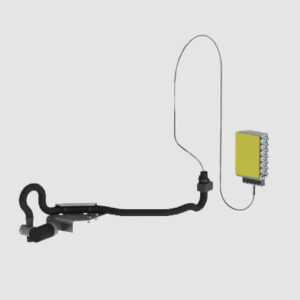

Electronic Feeder

To optimize cutting speed and quality each cutting head is connected to an electronic abrasive dosing system (feeder) located on each cutting head’s carriage and containing a small integrated buffer to ensure reliable, consistent and continuously variable abrasive addition.

Technical specification

| 2D Cutting head | |

| Maximum working pressure | 4000 bar |

| Pneumatic valve | opening pressure 6,5 bar |

| Water nozzle | 0.25mm/ 0,35mm/ 0.4mm |

| Abrasive mixing tube | Standard 0,76mm and 1.02 mm |

2D Cutting head Options

The cutting head can be extended with several options and features to further improve your waterjet cutting performance. Check out the following options to upgrade your cutting head!