Description

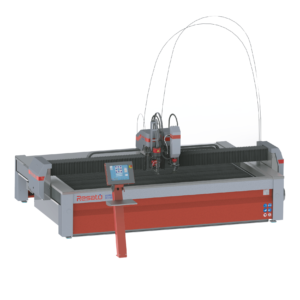

Flex-Zone More efficiency in a safe environment

While the table previously was unreachable during cutting, with the Flex-Zone it now can freely and safely be loaded and unloaded during the cutting process. Downtime is kept to a minimum while production and operator work-time is optimised.

Light curtains are normally placed around water cutting tables, guaranteeing operator safety. With the Resato ACM Flex-Zone, the safety feature is mounted on the bridge itself. It moves along with the working area of the cutting head. The Flex-Zone creates flexible, accessible work areas on the cutting table during cutting. Making the table accessible for operators during the cutting process.

Operation

The ACM Flex-Zone implements a front and back light curtain around the gantry at a specific distance to the cutting head and gantry. Crossing this light curtain while the machine is operating reacts into a direct stop of the cutting head and servo motors and offers a safe approach to the elements of the gantry.

The console offers within a few clicks a release of the protected zone and the cutting job can be resumed. While the cutting job is active the operator can load / unload outside the safety zone.