Description

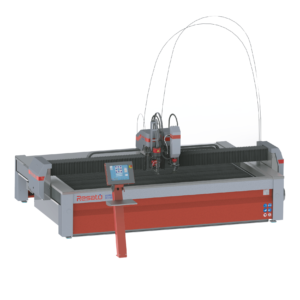

UWC

A semi-automatic water level control system can be installed within the catcher to permit faster water level adjustment. The water level is set and controlled via the HMI. Using the semi-automatic water level control, parts can be cut submerged, reducing both noise and water splash. The rear of the catcher is fitted with an “air clock”, operated from the operator console. The water level can be roughly set from 0 mm to about 50 mm from the cutting bed.

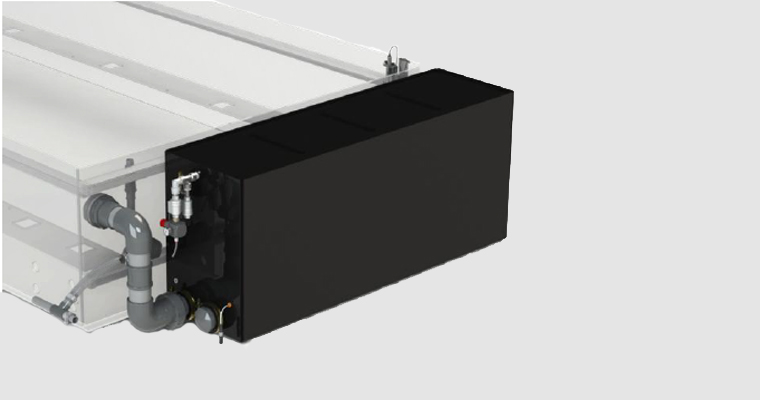

Cascade filter

The cascade filter is positioned between the overflow and drain of the catcher and is intended to reduce levels in the drain water of material cuttings and abrasives.

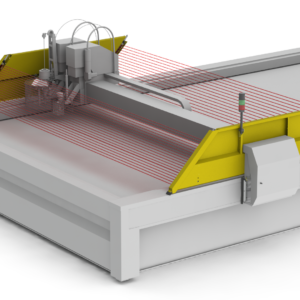

Remote control

The remote control unit allows limited operation of the machine away from the console and the movements of the cutting head to be controlled within the machine’s safety zone. The handheld control unit is intended to allow the safe movement of the cutting head into the correct position, for instance, to set a starting position that can then be adopted by the operator console. Once the cutting head is positioned, the machine can be operated from the operator console in order to ensure a safe working environment at all times.