Waterjet systems, the way to go for precision cutting

When you are looking for a smart cutting machine, there are numerous options. Although CNC and laser cutting systems are popular in the steel industry, waterjet cutting machines have their own advantages. These are particularly evident in the production of customized precision parts. In addition, the waterjet is also extremely versatile and suitable for fragile materials. Let’s take a look at the many benefits it has, how it compares to others, and when it can be the best cutting machine for your specific needs.

Precision Machining With Waterjet Systems

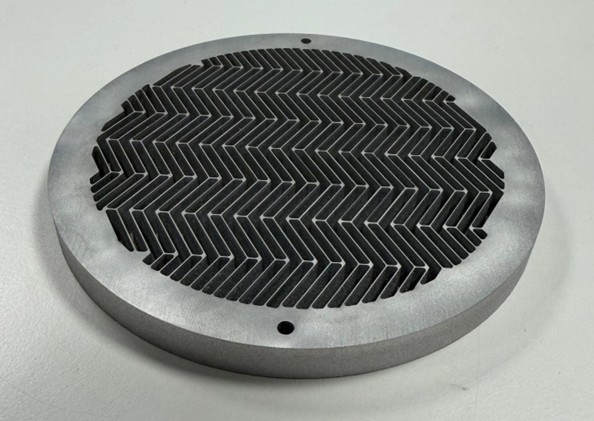

The main advantage of waterjet systems is their cutting accuracy. Once the first hole has been cut through the material, waterjet systems can achieve a tolerance of +/- 0.05 mm in the material. Resato waterjets can cut very tightly and versatilely in combination with this tolerance. The accompanying photo shows an air grille with 5 mm spacing between the bars. When you zoom in, you can see that the spacing is cut consistently and without deviations.

A waterjet system is also a very suitable machine to cut through thermally sensitive materials. Other cutting systems generate heat, while a waterjet generates no heat at all. This makes it ideal for materials that are sensitive to deformation when heated. Such deformation can result in the cut work being inaccurate or producing a completely different result than the design.

The accuracy of the waterjet is always high, but its versatility in cutting variations varies depending on the cutting head that is mounted on it. Resato offers both a 2D and 2.5D head. The 2D cutting head can only cut straight down, while the 2.5D head can cut both straight down and at angles up to 55 degrees, all with great precision and minimal deviation. This is ideal for refined products that cannot be cut with other cutting systems.

Precision Cutting Tools For Any Material

As mentioned, waterjet cutting systems offer many advantages over CNC cutting systems or lasers. For example, a waterjet can cut any material, such as metal, glass, stone, foam, rubber, plastic, food, composite, ceramics, wood, etc.

Another advantage of a waterjet cutting system is that it does not generate heat during cutting. This offers possibilities for materials that deform when cut with a laser or CNC. Examples include plastics or specific alloys that are at risk of elemental separation when exposed to high temperatures.

Compared to traditional methods such as milling and laser cutting, waterjet cutting wastes much less material. Where saw cuts are several millimetres thick, which means that patterns in the material are interrupted and visual defects occur, the waterjet cut is so thin that there are no visual effects. Milling techniques, by definition, process and remove the base material, which has a negative effect on material efficiency. This can have very negative financial effects, especially with expensive materials.

Also, an advantage of waterjet cutting is that no post-processing is required, which significantly reduces the time needed to prepare the product for delivery. Steel and metal in particular often require post-processing or sanding with traditional systems. With a waterjet cutting system, this is kept to a minimum, as it makes minimal changes to the product and leaves a clean-cut edge.

Waterjet cutting also offers advantages in the manufacture of products that would otherwise be manufactured using a traditional standard method. Examples include complex constructions for the building industry and precision concrete cutting. A waterjet is ideal for cutting basic elements for homes, such as pillars, posts, columns, smaller parts and tiles. Waterjet cutting systems are not only accurate but also reduce material waste compared to sculpting or hammering, thanks to the micrometer precision they offer.

Waterjet cutting is used in many industries for processing glass, metal, stone, car parts and textiles, for example. The waterjet excels in cutting unique parts, special designs and customized products. In short, products that all require precise attention to detail.

Comparison of precision cutting techniques

Waterjet systems are often compared to laser cutting in the metal industry. Although laser systems are generally faster, they are not suitable for thicker materials. The range of a laser is up to approximately 25 mm for low-carbon structural steel. A waterjet cutting system, on the other hand, has a range of up to approximately 200 mm thick for any material.

Compared to precision die cutting, waterjet systems offer a cleaner finish, cut without heat generation and have tighter tolerances. Waterjet systems can also cut automatically without constant supervision. Waterjet systems are less suitable for high-volume production, both in terms of scale and cutting costs.

When it comes to CNC machines, water cutting scores much better in terms of precision. Waterjet cutting offers a wide range of usable materials and is much faster for heavier materials, whereas CNC works better with softer materials. For plastics, for example, a water cutter is much more suitable than a CNC machine, because the CNC generates heat that can melt the plastic.

As mentioned earlier, an advantage of waterjet systems over all other methods mentioned is that the end product is created without heat and does not require finishing. Waterjet cutting should not be considered a mass production technique, but rather a versatile and adaptable process that produces quality products relatively quickly.

In general, waterjet systems are best suited for versatile and precise cutting. They cut through virtually any material, are highly accurate and the material is not deformed because no heat is released. Although other processes may be faster (CNC) or slightly more accurate (laser), waterjet cutting offers a good alternative with many more applicable possibilities.